Research:

Sustainability and Environment

Carbon Narratives for Design Planning

2020-2023

Embodied carbon in building materials and construction activity represents a significant fraction of the global greenhouse gas (GHG) emissions causing climate change. Concrete, iron, and steel alone produce approximately 9% of annual global GHG emissions and the combined embodied carbon emissions from the building sector currently produce 11% of annual global GHG emissions. This trend, if unabated, is anticipated to be responsible for almost half of total new construction emissions between now and 2050.

Research Lead: Mark Fretz, UO College of Design

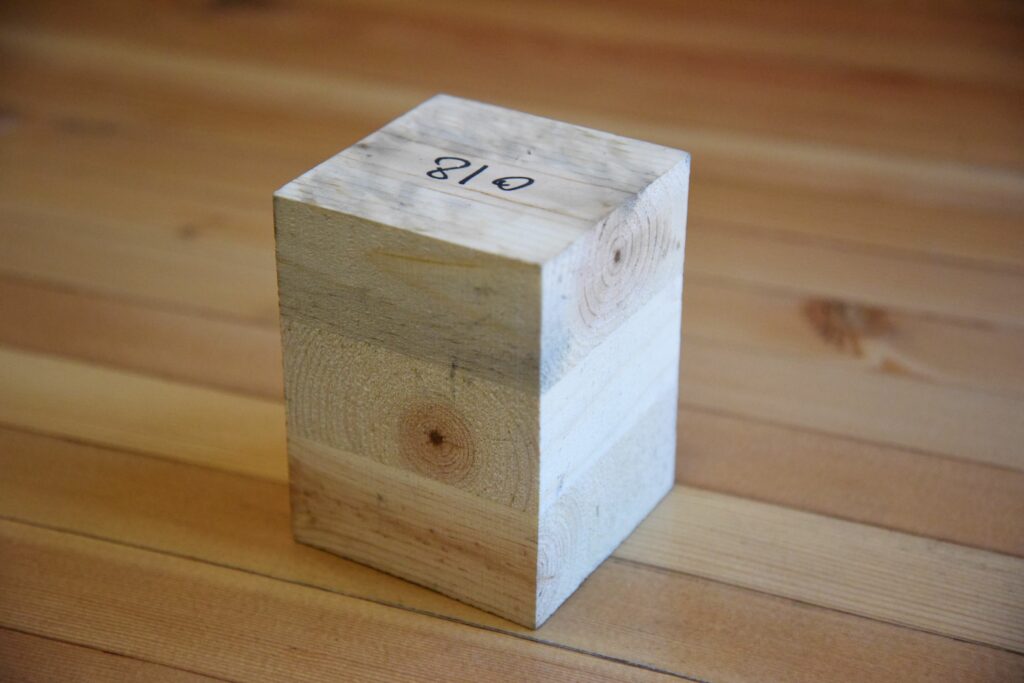

End-of-life Disassembly and Re-use of Mass Timber

2020-2023

The building sector is a major contributor to human environmental impact through the use of energy, emissions of greenhouse gases (GHGs), and extraction of raw non-renewable materials. Buildings have finite lifespans, and the materials from their end-of-life (EOL) can be either a burden that must be disposed of or a resource that can be reprocessed and used in place of virgin materials, offsetting associated manufacturing impacts in terms of direct costs and GHG balance.

Project Lead: Lech Muszynski, OSU College of Forestry

Defining Custom CLT Grade Utilizing Low‐Value Ponderosa Pine

2018-2021

The general aim of the USDA FS 2017 Wood Innovation program is to significantly increase or stimulate markets for wood products utilizing low‐value small‐diameter material generated in National Forest System restoration programs.

Research Team: Dr. Lech Muszynski, Dr. Mariapaola Riggio, Dr. Rakesh Gupta, Dr. Jeff Morrell (USC, Australia)

Environmental Impact of Mass Plywood Panels

2018-2019

This project will assess the environmental impacts of mass plywood panel manufacturing, a new product that has become available commercially in Oregon in 2018. It will examine material flow, energy type, and use, emissions to air and water, solid waste production, and water impacts for the MPP manufacturing process on a per unit volume basis using a cradle-to-gate life cycle assessment process.

Project Lead: Arijit Sinha

Environmental Assessment of MPP

2018-2019

Mass timber products are often selected for their perceived sustainability advantages, and a lifecycle analysis for an Oregon-based CLT manufacturing facility is being completed. This project will assess the environmental impacts of mass plywood panel manufacturing, a new product that has become available commercially in Oregon in 2018.

Project Lead: Arijit Sinha

Carbon Impacts of CLT

2018-2019

This series highlights five whole building life cycle assessments of buildings incorporating the building material known as cross-laminated timber into some or all of their structure, using a primary cradle-to-grave system boundary. The case study report will serve as an educational resource for academics, professionals, and CLT project stakeholders. (2018-2019)

Project Lead: Alison Kwok

Creative Applications of Fabrication off-cuts

2018-2019

This project captures off cuts and remaindered materials from structural testing at TDI in both CLT and MPP panels.

Project Lead: Linda Zimmer and Cory Olsen, UO College of Design

Life Cycle Analysis of Old and New Peavy Hall

2017-2019

This project assesses and compares the environmental impacts of forest products used in the old (1999) Peavy Hall teaching building at Oregon State University and the new mass timber building that will be completed in 2018. The findings will be incorporated in updated guidelines for life cycle analysis that fully take into account the role of reclaimable wood building products.

Project Lead: Paul Frederik Laleicke

Exploratory Study of Salvaged Lumber as Feedstock for CLT

2017-2019

The US generates 70 million tons of wood waste every year. To improve wood waste, cities like Portland, Oregon have implemented a deconstruction ordinance that requires buildings of a certain vintage to be deconstructed instead of demolished. This ordinance stimulates new markets for salvaged materials, but concerns of market saturation exist for salvaged lumber of shorter length and smaller dimensions. Mass timber products, like cross-laminated timber.

Research Team: Dr. Laurence Schimleck