Exploratory Study of Salvaged Lumber as Feedstock for Cross-Laminated Timber (CLT)

Research Team

Dr. Laurence Schimleck

Graduate Research Assistants:

Raphael Arbelaez, M.S.

Research Advisory Group:

TallWood Design Institute

Project Duration

2017 – 2019

Facilities

Oregon State University (OSU) Wood Science and Engineering Lab

Introduction

The United States (US) generates 70 million tons of wood waste every year with a recycling rate ranging between 10 to 15 percent. To improve recovery and use of wood waste, cities like Portland, Oregon have implemented a deconstruction ordinance that requires buildings of a certain vintage to be deconstructed instead of demolished. This ordinance stimulates new markets for salvaged materials, but concerns of market saturation exist for salvaged lumber of shorter length and smaller dimensions. Mass timber products, like cross-laminated timber (CLT), could provide a new value-added market for this material, but minimal research has examined the performance of panels made using a salvaged raw material. This study suggests that salvaged lumber could potentially be a new source of raw material for mass timber products, which could create new opportunities for wood waste recovery and greener building products.

Research Details

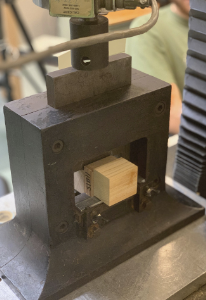

Salvaged lumber from Portland deconstruction practices was collected, graded, and processed for mass timber panel manufacturing. Three-panel layups were tested, each consisting of 3-ply panels measuring 45” by 90”. Layups included: 1) 100% salvaged lumber, 2) panels having virgin lumber outer plies and a salvaged core, and 3) panels with salvaged lumber outer plies with a medium-density fiberboard core. Panels were manufactured and tested at OSU according to ANSI/APA PRG320-18, “Standards for Performance-Rated Cross-laminated Timber”. Samples from these panels were tested for long-span bending tests, short-span bending tests, block shear tests, and delamination tests, and performance was compared to that of 3-ply E3 grade CLT and PRG320 prequalification criteria.

Results

All panels made with 100% salvaged lumber or virgin outer plies with a salvaged core passed structural performance criteria for E3 grade 3-ply CLT. Though nearly all panels passed delamination criteria, only one panel comprised of 100% salvaged lumber panel passed all qualification criteria as per ANSI/APA PRG320-2018.

Future Work:

This project represents an exploration of the potential to up-cycle used dimension lumber into engineered wood products such as CLT. Results are promising, suggesting that future work should focus on larger-scale testing efforts and a focus on resin application to determine the causes of delamination. It appears that the mechanical performance of such reclaimed products will prove adequate, and so future research should also focus on feasibility studies investigating the supply chain and manufacturing obstacles related to working with reclaimed wood.

Funding Acknowledgements:

Funding for this project was provided by the TallWood Design Institute (TDI) through a US Economic Development Administration (EDA) grant.

Acknowledgments:

Project partners, advice, and material donations: Henkel, NW deconstruction specialist/Reclaim NW, Good Wood, rebuilding center, Arauco, Stimson lumber, city of Portland, Portland metro, Metriguard.